If you are in the oil business, or drilling, or plumbing business, you are always measuring pipes. You also need to know the outside diameter of pipelines and pipe fittings that are part of a piping system. How do you do that without cutting the pipeline and measuring the diameter directly?

- Use a caliper, and transfer the measurement to a metal rule. This works, but is only as accurate as the metal rule, and your ability to transfer the distance to the rule. Also, who wants to carry around a caliper all day?

- Use an OD micrometer. But what size micrometer do you need? A 0-1 mic will only measure a pipe that is less than 1 inch in diameter. A 1-2 mic will only measure a pipe that is between 1 and 2 inches in diameter. Who want to keep a whole set of mics with them in the field?

- Use a flexible measuring tape, wrap it around the pipeline, make a reading and divide by pi. This works, but it’s not that accurate because the markings are on the side of the tape that is not physically next to the pipe. Your are really measuring the diameter of the pipe plus twice the thickness of the tape.

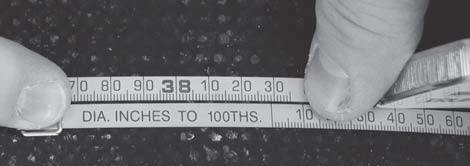

- At last, the best and easiest way to get the diameter of a pipe: Use a Lufkin Pipe diameter measuring tape. The diameter tape does all the work for you! Just wrap it around the pipe and read the diameter.